EXPLORATION SERVICES

Mineral exploration is the process of discovering minerals containing valuable materials, often on the surface of the planet or, increasingly, at depth.

The key aspects of exploration are really to further develop your understanding of the geology. From an initial analysis, companies may consider further expenditure, often using the techniques of geophysics or geochemical analysis to enhance existing data to drive informed decisions on future drill programs.

“GREENFIELDS EXPLORATION” is where exploration companies go into remote locations where few people, if anyone, has looked before.

“BROWNFIELDS EXPLORATION” is defined as exploration close to existing mines, trying to find new satellite type ore bodies that can be fed into the existing processing plants.

SMGC has experience in all aspects of exploration from greenfields to brownfields exploration of provincial scale concessions, to pre-production, extending existing operations and grade control sampling.

DATA COLLECTION

Geophysics uses a lot of computer power to process data collected in the field to enhance it and extract the content to be used in the geological interpretation we display as geophysical maps, images and 3-D models. These images and models are then interpreted by the geophysicist or the geologist to extract and convert the geophysical information into geological information. This is used to target minerals and pass on to the next stage of the exploration process.

Using Minex, Surpac, Micromine, Minescape, acQuire and other mining software, SMGC is able to collect, manage and interpret the data required to build geological models. In partnership with our clients, the planning and supervision of drilling programs can be conducted using state-of-the art software. Geological data can be enhanced by interpreting magnetics, gravity, radiometric and seismic data.

GEOLOGICAL SERVICES

Geophysics is the study of the interior of the earth using principles of physics. This means taking measurements at or above the earth’s surface to find out what’s beneath our feet and creating an image of those geological features. The 3 dimensions that geophysics allows is like having X-ray vision, to look into the earth to see and understand the structure and history of potential ore bodies.

Geophysics in a mineral exploration setting allows us to look into the earth and identify structures and different rock types. We can’t necessarily determine what is gold, nickel, copper, or iron, but we do start to get a picture of the rocks that are either metal-containing or potentially metal-containing from those that are not.

The geology provides information on where rock types are or where there are changes between the rock types. The geophysical survey connects to the geological mapping. Often looking at connections between rock types in the third dimension, at depth, using geophysical techniques will give you this information.

To produce sound geological models, SMGC uses a variety of structural tools including wireframing, ore body geometry, seam or vein modelling and geostatistical skills. SMGC uses these models to provide technical advice relating to exploration and mining geology. We also like to use multiple methods at the same time or on the same area, to give greater confidence. Interpretation is the key to a valid geological model and Resource estimate. Geochemistry, geology and geophysics techniques are used together to give a more definitive indication of whether there’s a mineral deposit in the ground that’s worth excavating.

OPTIMISATION

SMGC’s cutting edge pit optimisation techniques are able to incorporate all facets of the mine operation into true Life of Mine solutions. SMGC uses the Lerch Grossman and floating cone 3D pit optimiser to provide NPV-based LOM solutions that integrate full mine production scheduling. Whittle optimisation is another option that may be seamlessly incorporated.

Additionally, SMGC in association with Whittle consulting allows optimisation to be extended to full Enterprise Optimisation should the client require it.

DRILLING

The drilling phase of mineral exploration is the first time explorers can directly observe and analyse the rock beneath the surface of the earth. Drill holes can be targeted using geological maps, rocks observed in the field, magnetic or gravity geophysical data or geochemical information from soil samples where areas of elevated gold, coal, nickel, or other mineral levels form the focus of drilling efforts.

A typical drilling operation draws upon the expertise of geologists, geophysicists, field samplers, drillers and laboratory personnel. SMGC’s geologists determine the areas, spacing and priorities for the exploration drilling. Drilling rigs are then are used to extract samples from the site.

Drilling methods vary according to the size of the project area, budget, type of rock, topography, or mineral being targeted. Holes are drilled either vertically or at an angle to various depths. The rock is broken by the drill advancing through the rock or soil and returned to the surface as cuttings (small pieces of rock) or as core (solid cylinders of rock or clay). The drilled material is then collected and sent for laboratory analysis.

There are a range of exploration drilling methods that can be used but the most common methods are: reverse circulation (RC) and diamond core drilling.

SMGC works with a number of experienced drilling companies, dependent on the location of the concession and the type of mineral.

ECONOMIC ANALYSIS

If we ask the question: “For every dollar invested in greenfields exploration, “do I get 50 cents back…”, which wouldn’t be very good, “..or do I get my dollar back, or do I get $1.50 or $2?”

SMGC provides high-level economic analysis as an important step in creating an Ore Reserve from a Mineral Resource. Economic analyses are based on pit optimisation and block ranking methods applicable to surface mining.

Economic analysis is also used to defermine the highest value strategic plan for the entire business from exploration through to geological modelling, cut-off grade analysis, pit design, scheduling, dumping strategy, equipment selection, mine operations, product blending, logistics and product marketing.

MINE PLANNING

Evaluating, designing and scheduling the life of mine requires a rigorous planning process. Mine planning needs to address factors such as overall project value, sustainability, community expectations, mining methods, technical and practical considerations, infrastructure, processing, marketing and workforce options. Each planning stage considers the economic viability of the mine, weighing the business risks against the likelihood of turning a profit in a volatile mineral market.

Mine planning occurs every day in a mine, and it’s an ongoing process from pre-mining all the way through to depletion and mine closure. The purpose of mine planning is to connect the economics of what is believed to be in the ground from the exploration geology with the likelihood of being able to make a profit after investment in the mine, processing plant and other infrastructure.

How to mine it? How to process the ore into a product? How to transport the product? The mine planning function addresses these questions while considering the current commodity price exchange rates, costs, and grade of the ore body. All of these components will influence the revenue and cost streams, and thus the future cash flows for the project.

SMGC provides mine design and scheduling services for open cut and underground mines, with particular strengths in stratiform and thin vein deposits. SMGC is actively engaged in planning from high level conceptual studies through to operational planning. We support both pre-production and operating mines.

SMGC can provide the full cycle of mine planning services from short term operational planning to life of mine planning.

MINE INFRASTRUCTURE

Mines require an incredible amount of equipment and resources to operate. Having found a deposit that can form a mine, consideration must be given to the infrastructure requirements. This includes the transport in and out of goods, materials and people. It will also require a power source, water supply, communications, healthcare and everything else to service the workforce on site.

Infrastructure planning can be complex and involve large investments. It is the engineer’s role to design, plan and build fit for purpose infrastructure on time and under budget. The project may need water, power, road, rail, port and other supporting infrastructure. Mineral deposits are seldom blessed with convenient locations close to existing transport, infrastructure, workforce and customers.

Mining projects will either build their own road and rail infrastructure as a cost of the project or in a joint venture with other third parties or state authorities, particularly if there is a social benefits to nearby communities or the transport options become part of the state’s infrastructure. The same applies to port infrastructure, where companies may either build their own land-based port infrastructure or enter into arrangements with third parties or government authorities.

SMGC can help with infrastructure planning including, material handling, processing, power, water, haul roads, ports, camps and other project specific requirements. SMGC also helps mining companies to improving the efficiency and effectiveness of their existing assets. By considering the entire business, SMGC can interrogate current operations and provide an optimised plan to move forward.

EXCHANGE LISTING: COMPETENT PERSON REPORTS/ QUALIFIED PERSON REPORTS

SMGC has extensive experience in preparing Competent Person Reports and Qualified Person Reports for commodity exchanges globally. SMGC supports a number of clients in this role for their annual reporting and listing requirements.

DUE DILIGENCE

Due Diligence is a series of in-depth and comprehensive inspection and tracking processes with the aim of obtaining material information from a target company before a transaction or business cooperation is conducted.

The Due Diligence process aims to determine the potential risks and opportunities associated with the target project. This is done through a systematic process of enquiry, observation, investigation, analysis and verification of key aspects of the project being considered. Due Diligence is also conducted to determine the economic, technical and practical feasibility of projects. This can include the verification of reported mineral Resources or Ore Reserves.

Thorough Due Diligence studies demand the ability to examine in detail the essential factors that affect the final appraisal of a property. SMGC’s senior staff have a wealth of experience to guide clients through the potential risks and opportunities they may encounter.

SMGC’s Client list for Due Diligence assignments in Indonesia is as follows (certain clients have been omitted due to existing “Non-Disclosure Agreements”):

Merrill Lynch, Sumitomo Mitsui Bank, Genting Sanyan Group (Malaysia), Mitsubishi Corporation, Rajawali Group, Pacific HSE (Malaysia), Straits Amalgamated Trading and Resources Limited, TNB, Renaissance Capital Asia, Global Fuels Pty Ltd, Tridem Group, Stark Investments, PT Sojitz Indonesia, Across Asia Limited, PT Pama Persada Nusantara, South Gobi Energy, Carbon Partners, DBS, Standard Chartered, POSCO, PT ADI, Bumi Resources, Deloitte and Mitsui.

The Banks SMGC has provided services for in relation to Indonesia include (certain clients have been omitted due to existing “Non-Disclosure Agreements”):

International Banks: – Sumitomo Mitsui Bank, Credit Suisse, BNP Paribas, DBS, Standard Chartered, Barclays, Standard Bank, Macquarie, JP Morgan, Deutsche Bank, UBS Bank, Merrill Lynch, CITI Bank, ANZ Bank and HSB.

Indonesian Domestic Banks: – CIMB Niaga, Bank Mandiri, BNC and DBS Indonesia

SMGC completed a report used to support funding on a US$1.2 billion transaction for a Central Kalimantan coal concession.

GEOGRAPHIC INFORMATION SYSTEM (GIS) SERVICES

SMGG’s geographic information system (GIS) captures, stores, checks, and displays data related to the concession’s position on Earth’s surface. By relating seemingly unrelated data, the GIS can help individuals and organizations better understand the spatial patterns, relationships and prospectivety of concessions.

SMGC has worked on many coal and metals projects across Indonesia and has over 3,000 projects on our Geographical Information System (GIS) data base.

SMGC’s GIS is integral in the preparation of Due Diligence projects, JORC Resource and Reserve reports and Feasibility Studies for projects in the South East Asia region.

SMGC has also worked on a number of projects identifying suitable locations for Logistic /Power Plants/Mineral Processing Plant projects in Indonesia where SMGC’s GIS knowledge has been critical to the project’s success.

DRONE SERVICES

Drones have made it possible to map a mining concession area very quickly in a very cost-effective manner, compared to the traditional methods of ground survey, manned aircraft and satellite imagery. The mining industry is now extensively using drone mapping and surveying, to monitor mine operations and conditions. Drone surveys can also be used to measure surface elevations and volumes to track the progress of mining, dumping and stockpiling operations against the plan. With this almost real-time monitoring, prompt remedial actions can be implemented to re-align operations to restore compliance with the mine plan to maximise project value.

Surveying with a drone offers enormous potential. With a drone, it is possible to carry out topographic surveys of the same quality as highly accurate measurements collected by traditional methods, but in a fraction of the time. Often it is possible to capture the entire pit, dumps and mine infrastructure in one detailed flight. This provides engineers and planners with a greater understanding of the entire concession. This substantially reduces the cost of a site survey and the workload of specialists in the field.

SMGC owns a variety of drones that are being used for surveying, mapping and general data collection during site visits. This provides SMGC’s engineers with a greater insight of the whole project and the ability to advise clients on a “Live” basis.

The use of drones by SMGC during Due Diligence assignments allows a rapid assessment of the site with recorded evidence of any observed issues.

JORC CODE

SMGC is a leader in the estimating and reporting of Mineral Resources and Ore Reserves in accordance with the JORC Code across a range of mineral commodities. Several staff members have extensive experience which qualifies them as “Competent Persons” as defined in the JORC Code. SMGC partners with clients through all stages of prospecting to ensure the integrity and quantity of exploration data is sufficient to enable estimation and reporting of Resources and Reserves in accordance with the JORC Code. SMGC’s senior staff have a wealth of experience to guide clients through the potential risks and opportunities they may encounter.

KCMI CODE

SMGC is also a leader in the estimating and reporting of Mineral Resources and Ore Reserves in accordance with Indonesia’s KCMI Code. Several SMGC consultants currently hold “Competent Person Indonesia” certification across a range of deposit types. SMGC partners with clients through all stages of their project’s life to enable estimation and reporting of Resources and Reserves in accordance with the KCMI Code. SMGC’s senior staff have a wealth of experience to guide clients through the potential risks and opportunities they may encounter.

NI43 – 101

For companies wishing to list on Canadian stock exchanges, SMGC can report Mineral Resource and Ore Reserve estimates in accordance with the rules and guidelines of the Canadian National Instrument 43-101 (NI43-101). SMGC partners with clients through all stages of their project to ensure the integrity and quantity of exploration data is sufficient to enable estimation and reporting of Resources and Reserves in accordance with the NI43-101. SMGC’s senior staff have a wealth of experience to guide clients through the potential risks and opportunities they may encounter.

VALMIN REPORTING

SMGC is a leader in the reporting of mineral assets in accordance with the VALMIN Code. Keith Whitchurch qualifies as a Practitioner and Specialist as defined under the VALMIN Code. SMGC partners with clients through all stages of their listing, public reporting valuation processes. SMGC can provide public reports for Mineral Assets including Technical Assessments, Valuations and Independent Expert’s Reports also known as Independent Qualified Person’s Reports (IQPR). Mineral Asset Valuations can be done using multiple approaches including market based, income based and cost based methods. SMGC has a wealth of experience to guide clients through the public reporting process including confirmation of the requirements of the different listing exchanges.

CONCESSION MAPPING

Generally built on existing maps from government or other sources, geologists will spend time in the field observing landscapes, rock formations and mineral outcrops. This will also include collecting grab samples and recording interpretations to create a high-quality map of the concession.

SMGC has in-depth experience in mapping concessions for many minerals. SMGC can provide a mapping team to review your concession and provide ongoing advice for future exploration programs.

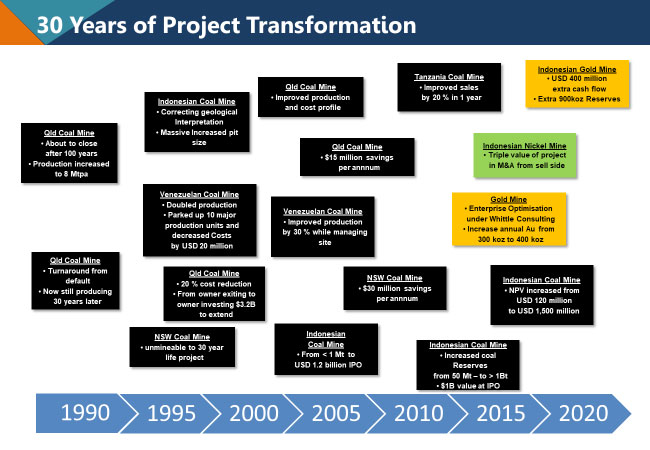

PROJECT TRANSFORMATION

SMGC has extensive experience in transforming projects across the coal and mineral sector. This often includes the turning around of distressed assets back to profitability. SMGC’s approach is to review all aspects of the business and provide a strategic path forward with a specific implementation plan to transform to the project and dramatically improve its economic viability.

MINERAL ASSET REVIEW

SMGC assists clients with initial concession reviews which are a quick look at the available data on the target asset. Initial reviews are key in the staged evaluation and transaction process to decide whether to continue with further review and due diligence or drop the project. This enables clients to focus effort on the more prospective targets and not waste time on less attractive concessions. These initial mineral asset reviews normally take 3 – 4 days, depending on the available data.

EXPERT WITNESS

SMGC has supported many corporations and legal firms providing “Expert Witness’ services in areas of mineral quality, geology, mine planning, production and marketing.

PLACING COKING COALS INTO THE MARKET

SMGC has successfully placed a number of coking coals into the Japanese market. Understanding the quality of the coals and how they will perform in the coke ovens and blast furnaces can ensure the best outcome in placing specific coking coal brands into the market.

POWER PLANT SERVICES

Mine site power is key to mining operations and costs. SMGC can provide innovate power solutions based on each concession’s specific requirements.

EQUIPMENT SELECTION

One of the key decisions facing surface mining operation is the selection of the optimum equipment combination. This can include conventional truck and shovel systems as well as other alternatives such as in-pit crushing and conveying (IPCC), surface miners and draglines. SMGC can assist with this initial selection based on various site factors and then then further optimise the selected system.

IN-HOUSE TRAINING

SMGC can provide clients with in-house training in exploration, geology, engineering and mine planning for technical or non-technical participants.

INDUSTRY PARTNERS

As required, SMGC will collaborate with different industry partners to bring in specific expertise to suit the requirements of each project.

QUALITY ASSURANCE/QUALITY CONTROL (QA/QC)

QA/QC programs need to be carefully designed and implemented at all stages of exploration and development where sampling of material is undertaken. Furthermore, QA/QC programs require review prior to, and during, each sampling program with modifications made where necessary based on numerous factors such as sample type, size, and the proposed sample processing and treatment methods.

QA/QC is required to ensure all geological data generated over the course of a sampling program (exploration or development) adheres to the key fundamental aspects of:

- Accuracy – the degree to which an analysis is reflective of the expected result.

- Precision – the repeatability of the result, and

- Identification of sampling failures/errors/contamination.

SMGC’s geologists provide and train clients with QA/QC procedures based on the requirements each specific project.

TRENCHING

Trenching or test pits can be a key part of the exploration process where conditions require a certain method of sampling to remove overburden that is covering the mineralisation.

Trenching involves removing a shallow amount of surface material to expose a vertical section of mineralised zone.

SMGC can assist with the design of the trenching plan and QA/QC support. SMGC can provide onsite assistance and support to client throughout the process.

RESOURCE MODELLING

SMGC geologists have extensive experience in exploration, database management, geological modeling, Resource estimation, conditional simulation, technical reporting across all ore types and international Resource reporting codes across the world. Each mining concession is unique in its geological structure, quality, ore grade, chemistry, moisture and density values. SMGC geologists create 2D and 3D geological models based on the individual mineral deposit. All date received is checked and verified.

SMG Consultants was borne out of the Surpac Minex Group. SMGC continues to work with Dassault Systémes, the owners of the MINEX software to develop its interpretation and modelling of geological and technical data.

SOFTWARE TRAINING

SMGC works with clients to design tailored programs to train geologists and engineers in using and interpreting data across a number of mining software systems.

MINE MANAGEMENT

SMGC is well placed to provide mine management services to clients for both coal and metals mines. Mine management services cover all aspects from Pre-Production, operations and closure.

SMGC will construct a team based on the concession’s operational requirements.

SCOPING, PRE-FEASIBILITY STUDIES AND FEASIBILITY STUDIES

SMGC provides a full range of reports to clients to meet their requirements for development, construction, production, financing, and government.

MINERAL PROCESS PLANT DESIGN

Mineral processing is the art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining to provide a more concentrated material for the subsequent stages of extractive metallurgy. Designing and building a mineral process plant requires a detailed study of the physical and chemical properties of the ore.

SMGC can assist clients to design and build processing plants to cover the following:

- Identifying mineral ore processing requirements

- Mineral ore classification

- Liberating disseminated and bulk ores

- Comminution

- Milling

- Separation and concentration

- Gravity

- Flotation

- Chemical Leaching

- Magnetic and electrostatic

- Refining and smelting

COAL WASHERIES

SMGC is well versed in the design, operation and technical review of Coal Handling and Preparation Plants (CHPP). CHPP’s are required for receiving, crushing, sorting, washing, stockpiling and loading of product coal onto transport units for shipment to market.

CHPP’s can include the following processes:

- Handling

- Sampling

- Washability

- Crushing

- Screening

- Gravity Separation

- Fine Coal Methods

- Dewatering

- Implement Control Systems

METALLURGICAL TEST WORK

SMGC is supported by a number of metallurgical engineers to support the requirements of our clients. Our services cover sampling advice, monitoring exploration, analysis of laboratory samples, preparation and review of plant flow sheets to support ongoing reporting requirements, extraction and mineral processing.

GEOTECHNICAL SERVICES

SMGC is supported by a range of third-party service providers for geotechnical services.

TOPOGRAPHICAL SERVICES

SMGC’s drone services provide SMGC’s clients with topographical services for greenfield concessions and operating mines. SMGC analyses all data internally to provide clients with ongoing feedback and topographical either as stand-alone reports or to support Due Diligence Reviews, JORC/KCMI Resource and Reserve Reports.